Warehouse Lighting Buyer’s Guide: 10 Essential Must Read Buying Tips?

Product Introduction

Warehouse Lighting Buyer’s Guide: 10 Essential Must Read Buying Tips?

Poor lighting creates confusion. A clear lighting plan fixes it fast.

Good warehouse lighting starts with a plan, not just fixtures. Understand your needs before spending.

Don’t waste money. Learn what actually matters when choosing warehouse lighting.

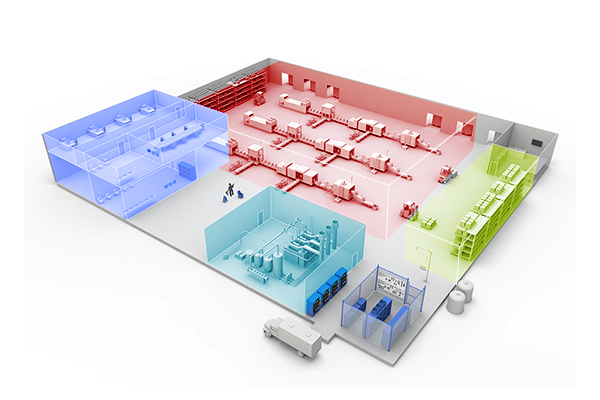

The Key to Adding LED Lights in a Warehouse is to Start with a Lighting Plan?

Bad lighting creates accidents. A lighting plan solves this before it starts.

A warehouse lighting plan helps you choose fixtures that match layout, height, and work zones.

A proper plan makes everything easier. When I first upgraded our warehouse, I skipped this step. Big mistake. The new lights caused glare in one zone and shadows in another. I had to start over. That’s when I learned: start with a blueprint.

Why a Lighting Plan Matters

A warehouse is not just a big room. It has aisles, shelves, open work areas, and sometimes loading zones. Each space has its own needs.

Things a Good Lighting Plan Considers

|

Item |

Why It Matters |

|

Ceiling Height |

Impacts beam angle and fixture selection |

|

Shelf Layout |

Affects shadow patterns and spacing |

|

Task Zones |

Dictates brightness levels |

|

Natural Light Sources |

Helps save energy by adjusting lighting placement |

|

Existing Fixtures |

May limit or guide fixture upgrades |

Tips for Building Your Plan

- Measure the full space, not just floor area.

- Sketch zones and tasks. Don’t forget breakrooms and storage.

- Use software or ask suppliers for a photometric layout.

A good plan makes buying easier. It shows what types of lights, what brightness, and how many units you actually need.

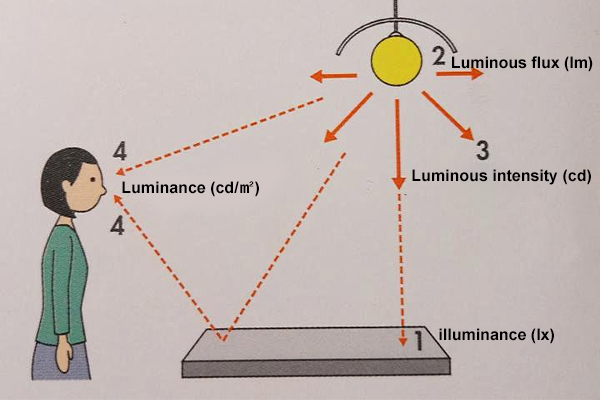

Determine Your Required Light Levels. Forget About Watts?

Using watts to judge brightness is outdated. It leads to under-lit or over-lit spaces.

Use lumens and foot candles to calculate how much light your warehouse needs.

I once thought, “Just get 100W LEDs. That’s bright enough.” I was wrong. Wattage only shows energy use, not brightness. I learned about lumens and foot candles the hard way, after workers complained it was still too dark.

Lumens vs. Watts

- Watts = how much energy the light uses

- Lumens = how much light the fixture gives off

What really matters in a warehouse is foot candles, which measure light reaching the surface.

Suggested Light Levels

|

Area Type |

Recommended Foot Candles |

Notes |

|

General Storage |

10–20 FC |

For areas without much activity |

|

Active Aisles |

20–30 FC |

Needed for visual tasks |

|

Packing Zones |

30–50 FC |

Higher for detail visibility |

|

Inspection/Detail Work |

50–70 FC |

Precision requires more light |

How to Measure

- Use a light meter for real-time readings.

- Ask lighting vendors for a photometric report.

- Match lighting layout to your required foot candle levels.

By focusing on light output and surface brightness, you can avoid buying the wrong fixture just because it has “high wattage.”

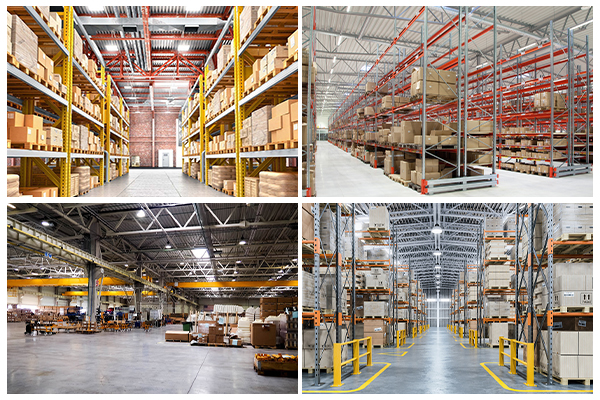

Decide on the Type of LED Warehouse Lighting Fixture That Best Fits Your Needs?

Choosing the wrong fixture wastes money. The right one lasts years and works better.

Different LED fixtures suit different warehouse layouts and heights. Choose based on function, not looks.

When I first upgraded, I bought high bay UFOs because they looked industrial. But our ceilings were too low. Workers hated the glare. I returned half of them. That’s when I learned: fixture choice is about application, not just appearance.

Common LED Warehouse Fixtures

|

Fixture Type |

Best For |

Mounting Height |

|

UFO High Bays |

Open areas with high ceilings |

15–40 feet |

|

Linear High Bays |

Aisles and shelf rows |

12–35 feet |

|

Strip Lights |

Lower ceilings, tight areas |

Under 15 feet |

|

Vapor Tight |

Damp or dusty environments |

Various |

Key Questions to Ask

- What’s the ceiling height?

- Is the space open or shelved?

- Do you need impact/dust protection?

Other Fixture Considerations

- Dimming: Helps save energy in off-peak hours.

- Motion Sensors: Great for low-traffic zones.

- Color Temperature: 4000K–5000K works best for visibility.

Choosing the right fixture avoids eye strain, boosts safety, and makes the warehouse look professional. It’s worth taking the time.

Good warehouse lighting starts with a plan, correct light levels, and the right fixtures.